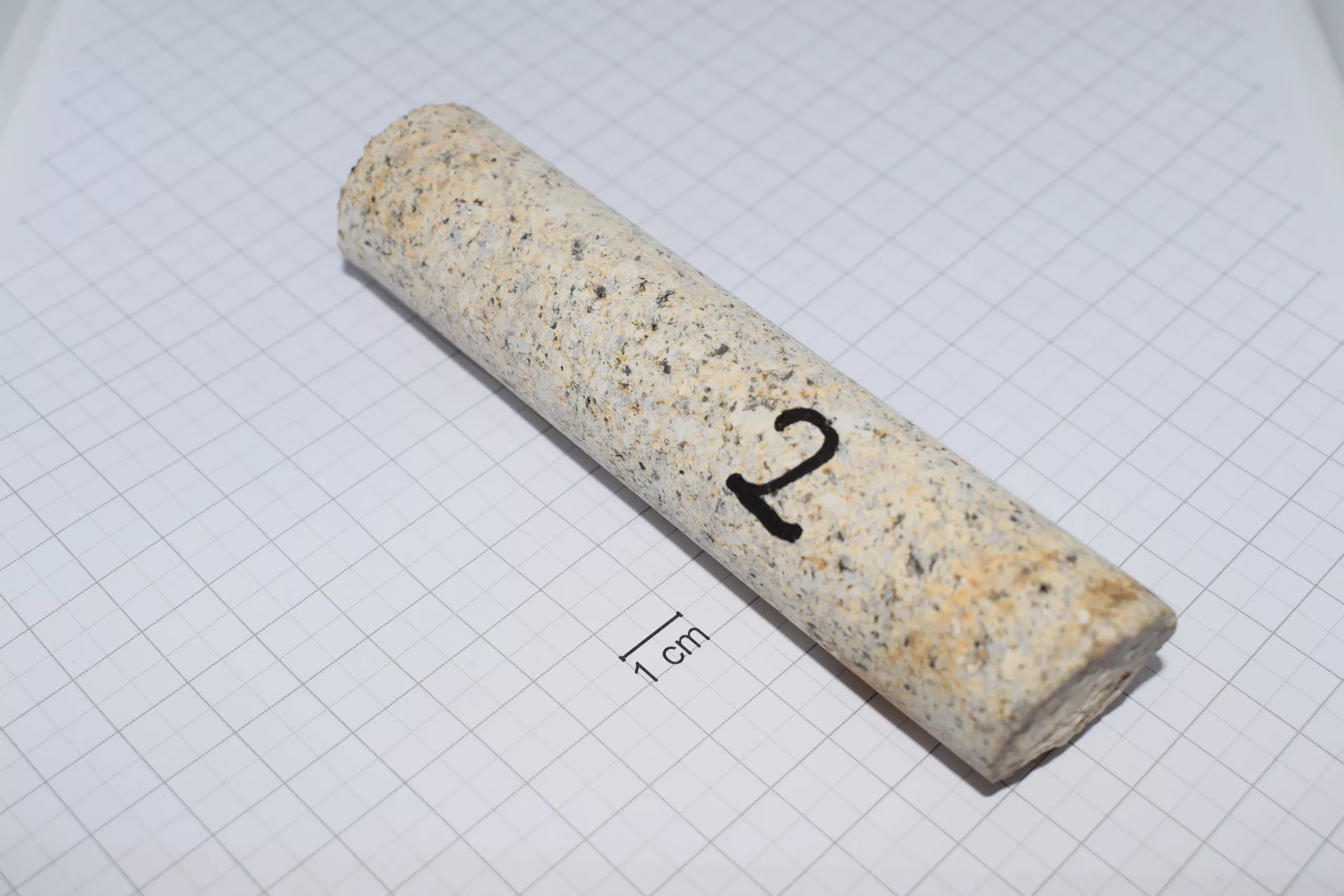

Coring on masonry elements

Mechanical coring, carried out by means of a drill rig, allows cylindrical samples to be taken from the masonry and a wall inner section to be observed directly, giving a clear view of the masonry composition and thus verifying the presence and location of discontinuities. It is possible to carry out both core drilling of walls for the analysis of the internal composition of the masonry (also using an endoscope) and the extraction and laboratory analysis of mortar/stone/brick samples, or sub-vertical drilling to assess the depth and nature of the foundations. In the case of heritage buildings, micro-coring is commonly chosen, with a smaller diameter (40 mm) and a depth ranging from 0.50 to several metres, in order to obtain maximum information with limited disturbance.